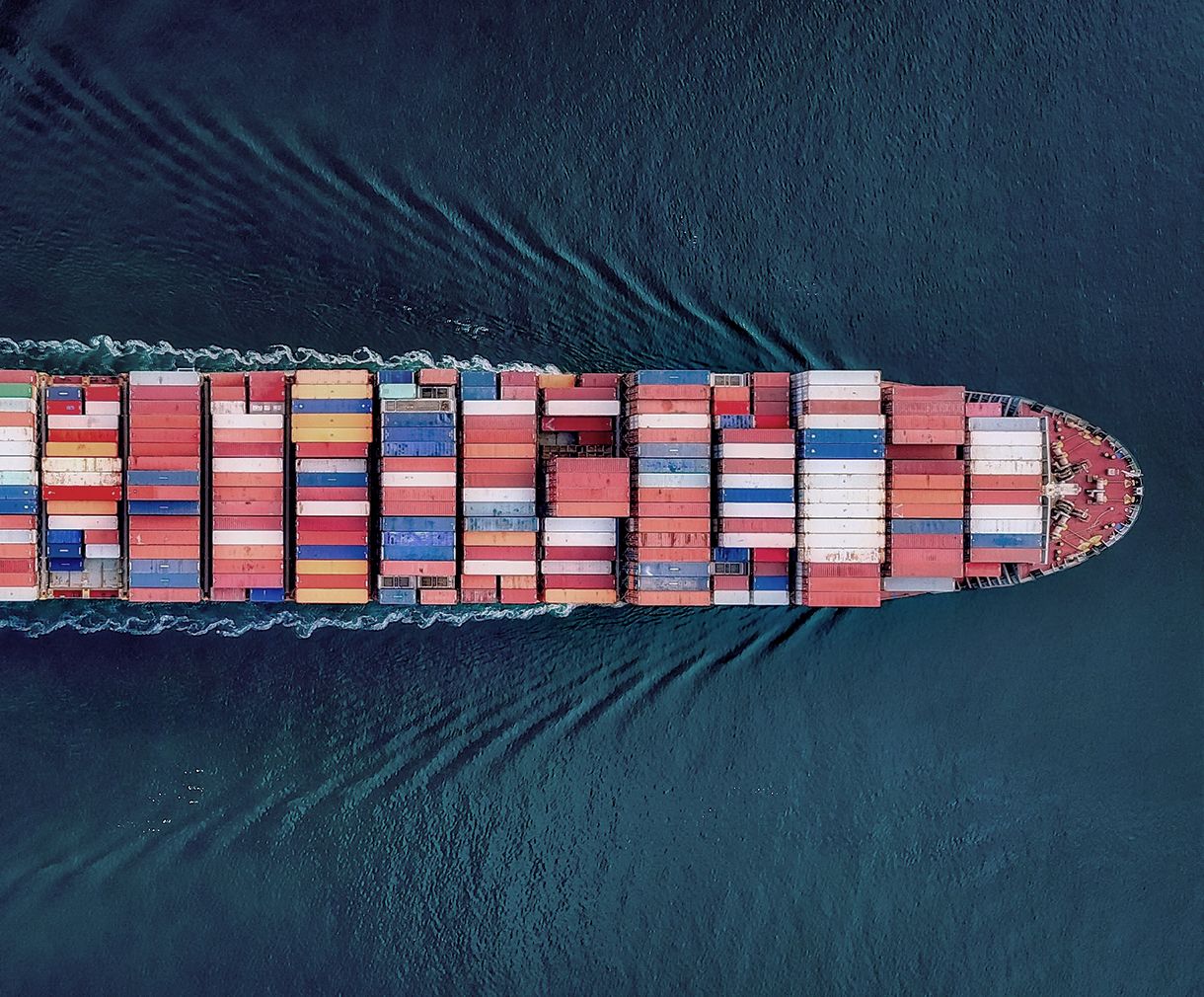

3 ways to reduce co2 emissions from sea freight

Remember that reducing CO2 in the logistics is a multipoint process. Historically, shippers — companies who need to move goods from point A to point B — have access to a quarterly report built atop their shipment history. This report summarizes scope 3 emissions, i.e....